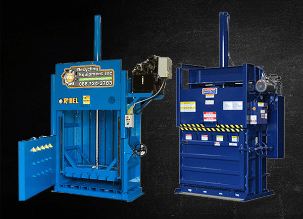

Vertical balers compact a variety of waste material for recycling or disposal by producing a dense bale of material. These machines can be an ideal introduction to baling and are able to handle moderate volumes of materials. Great for managing waste streams of up to 50 tons of material per month. The completed bale is tied using single loop bale ties.

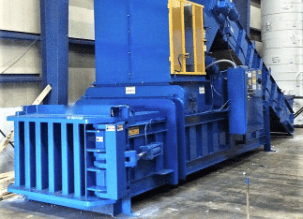

Typically fed by a conveyor system or tote tipper, this piece of equipment compacts a variety of material for efficient transport. Horizontal units can bale a wide variety of material including cardboard, paper, newspaper, printer trim, film, plastic parts and more. A closed-door horizontal baler will produce high-density bales up to 1,450 pounds and effectively manage waste streams between 50-200 tons per month. Completed bales are tied using bale ties.

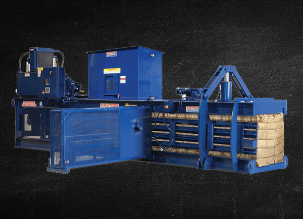

Open-End Auto-Tie balers compact fiber products including cardboard and paper materials while Two Ram balers can be used to bale a variety of materials including fiber, plastic, metal and more. Auto-Tie Balers are generally well suited to manage high volume productions and high throughput needs from 200 – 1,000 tons or more per month. The baler automatically ties off completed bales using stump or box baler wire eliminating “completed bale” downtime and reducing labor costs.

Bale Your Loose Material Waste

Industrial balers compact recyclable materials into dense, compact bales. These bales take up less space, making transportation and storage more efficient and cost-effective.

Cardboard

Plastic

Paper

Cans

Steel

Textiles

Foam

Don’t see your material listed? Call us at 260.494.5676 to discuss your options!

Common Challenges Customers Face

Transporting loose waste materials can be costly and inefficient. Industrial balers help businesses reduce transportation costs by compacting materials into dense bales that are easier to transport. Recycling waste material also allows companies to save on landfill and disposal costs.

Many businesses struggle with limited waste storage and processing space. Industrial balers, especially vertical balers, offer a compact solution for efficient waste management in small spaces. Their smaller footprint makes them a popular choice for businesses such as retail stores, restaurants, and small manufacturing facilities.

Handling loose waste materials can pose safety risks. Plants become unorganized, and workers and equipment can be at risk of stepping on or running into stray materials. Industrial balers provide a safer and more organized work environment by reducing the volume and space of waste materials and helping to minimize the risk of workplace accidents.

Benefits of Industrial Balers

Reducing the Volume of Waste

Why is reducing the volume of recyclable waste important? By reducing the volume, you reduce the space it occupies in warehouses and in trailers during transportation. This provides a cleaner work area while also reducing storage, fuel, and hauling costs. Quincy Recycle actively works with companies to pick up their recycled bales while offering top value for the materials.

Industrial balers are ideal for compressing bulk recyclable materials, including cardboard, paper, plastic, and metal. Sorting the recyclables into like-materials before inserting them into the baler will help to maintain the efficiency of your equipment. They are not ideal for compressing liquid waste or organic materials. If you are looking for equipment to compact your organic material, check out our industrial compactors or give us a call to discuss your specific need.

If you want to overcome waste management challenges and maximize efficiency in your operations, Quincy Recycle is here to help. Our extensive baler inventory is designed to meet the diverse needs of businesses in various industries.

Not sure which industrial baler is best for your business? Contact us today or call 260.494.5676 to talk with someone about finding the right baler for your budget and needs.