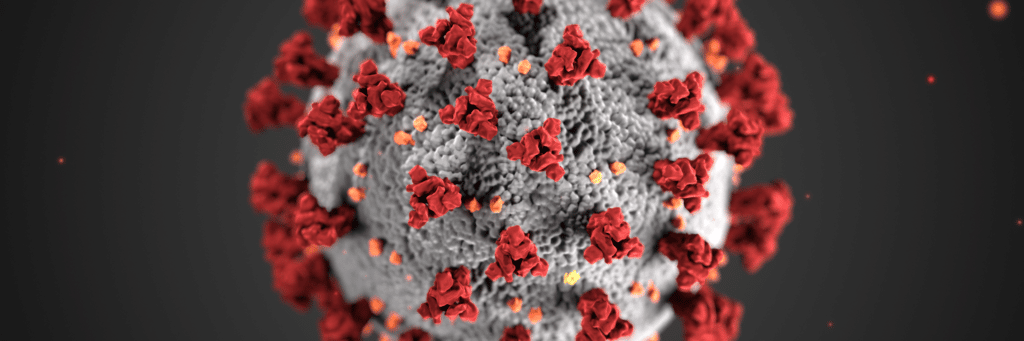

COVID-19 Response

Update regarding COVID-19

As the global pandemic of COVID-19 continues to affect communities all over the world, we wish to communicate to everyone how this affects our business and you as our partner. First and foremost, we want to communicate that our hearts go out to those who have been affected by this novel coronavirus.

Rest assured, Quincy Recycle is able to continue to responsibly operate at the level needed to keep our partners running.

What we are doing:

We have always placed the highest priority on our employee and partner safety and will continue to do so throughout this time. Within our facilities, we have adjusted operations and enhanced preventative measures in accordance with the CDC guidelines. We have instructed those with the capabilities of working remotely to do so to limit interaction of those on-site. For those on-site, we have limited person-to-person interactions.

What you should know:

We want you to know that our team is working diligently to adapt to your changing environments as you fill the necessities of the world. Your business is essential, and we are here to ensure that your needs are met.

We understand that we may have partners who have adjusted their production level or modified their material needs in response to COVID-19. Please know that Quincy Recycle is here to support your needs and we will do everything we can to create solutions for you.

Thank you for being a partner of Quincy Recycle. If you have any questions, please reach out to our customer service team by calling 800-311-6097.

Best,

Quincy Recycle Team

Your Partner in Recycling Commingled Plastic Loads

Quincy Recycle is your Partner in Commingled Plastic Loads

Managing single stream and dual stream residential is not an easy part of the industry. However, with a partner like Quincy Recycle who has an Optical Sort Line in Quincy, IL we can add value to your commingled and unsorted rigid container pack.

Why Choose Quincy Recycle for Commingled Plastic?

Quincy Recycle is equipped to handle your 1-7’s pack and any other combination of those containers efficiently. Their advanced sorting “Optical Sort Line” can process a variety of plastic types, including polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET) and more. This capability eliminates the need for Material Recovery Facilities (MRF’s), buy back-centers, and municipal and residential collection programs to separate plastics before disposal, allowing them to streamline their operations and focus on their core activities.

Expertise in Handling Diverse Plastic Materials

Commingled plastics can consist of #1’s, #2’s, #3’s, #4’s, #5’s, #6’s, and other rigid containers. Quincy Recycle’s experience in dealing with different grades and forms of plastic ensures that these materials are processed correctly and responsibly. By leveraging industry expertise, they maximize the amount of recyclable material and minimize waste, providing an eco-friendly solution that aligns with sustainable business practices.

Simplified Logistics with Pickup Services

One of the biggest challenges in managing commingled plastic is logistics. Quincy Recycle addresses this by offering flexible pickup options. Their fleet can pick up loads of commingled directly from your facility. This simplifies the entire waste management process and helps businesses and organizations to maintain continuity without the hassle of coordinating various recycling efforts.

Cost-Effective and Efficient Processing

Sorting and recycling commingled plastic internally can be costly, requiring specialized equipment and additional labor. By partnering with Quincy Recycle, businesses can avoid these expenses. Quincy Recycle provides a cost-effective solution by taking on the unsorted and sorted packs, and processing operations allowing vendors to reduce operational costs and increase efficiency.

Commitment to Sustainability and Business Value

While sustainability is an essential focus, Quincy Recycle’s approach emphasizes the business value of effective recycling. By turning what would be waste into a reusable resource, they help companies and organizations not only reduce landfill use but also extract maximum value from their waste streams. This creates opportunities for vendors to turn their plastic waste into revenue or savings, aligning environmental responsibility with business profitability.

Partner with a Trusted Industry Leader

With years of experience, Quincy Recycle has built a reputation as a dependable partner for businesses across various sectors, from manufacturing to retail. Their ability to handle diverse and complex waste streams makes them an ideal choice for vendors looking for an efficient, one-stop recycling solution. By partnering with Quincy Recycle, businesses, municipalities, and other organizations can be confident that their commingled plastics are being managed with expertise and care.

Learn more about how Quincy Recycle can simplify your waste management and maximize the value of your plastic recycling efforts by contacting us today!

How a Baler Can Transform Your Organization’s Waste Management

Bulk material waste can be hard to manage, especially when employees spend valuable time on organization, clean up, and removal.

Companies that manually handle materials like paper, cardboard, plastic, or metal scraps are likely familiar with the struggles of incorporating waste management into regular business operations.

By investing in an industrial recycling baler, your business could free up THOUSANDS of hours each year spent on manually handling waste streams.

Let’s look into specific situations where companies like yours can use a baler to transform your organization’s waste management.

How a Recycling Baler can Improve Waste Management

Situation 1: Excessive Waste Handling Costs

A mid-sized packaging manufacturer struggles with escalating waste handling costs. The company frequently contracts waste haulers to dispose of loose cardboard and plastic film.

Solution: After integrating a closed-door baler into their operations, the manufacturer compacts waste material into dense, easy-to-transport bales.

Outcome: Compacted bales reduce the volume of waste and frequency of waste pickups, and the manufacturer saves on waste management expenses and disposal fees.

Situation 2: Lost Revenue Opportunities

A regional distribution center manages large volumes of return goods packaging. Unknown to them, this “waste” contains untapped revenue potential.

Solution: By leasing two vertical balers one for cardboard and one for plastic, the DC can separate, bale, and move material quickly and effectively.

Outcome: Baled materials are purchased at fair market value by a recycling company and turned into an additional revenue stream for the distribution center.

Situation 3: Environmental Regulations Non-compliance

A bottled beverage manufacturer faces penalties due to failure to comply with environmental regulations related to waste management.

Solution: By implementing a waste management plan with a high-capacity horizontal baler, the company can divert plastic waste from landfills and ensure they meet regulatory standards.

Outcome: Proactive green initiatives mitigate the risk of penalties and promote the company’s reputation as an environmentally responsible business.

Situation 4: Inefficient Use of Space and Safety Hazards

A large company faces challenges with its retailer stores having limited space for waste management. Safety concerns arise due to the accumulation of cardboard and packaging materials on the warehouse floors.

Solution: Installing a vertical cardboard baler at each retail site allows the retailers with limited space to manage waste on-site promptly, freeing up valuable space and reducing the risk of accidents.

Outcome: The company contributes to overall cleaner and safer work environments.

Situation 5: Workers Spend Hours Dealing with Loose Waste Materials

Workers at a packaging plant spend hours flattening corrugated cardboard boxes and manually tying them together. A substantial amount of valuable labor time is spent managing waste streams.

Solution: Balers automate the process of waste compaction to remove the need for workers to engage in time-consuming, manual flattening and binding of boxes.

Outcome: The baler does the heavy lifting, baling waste fast and freeing up the team to focus on core operations.

Successful waste management for your business doesn’t have to be hypothetical.

At Quincy Recycle, we believe in transforming the challenge of waste management into an opportunity for your business. We evaluate your company’s waste production and management practices by conducting on-site audits. Our hands-on approach allows us to recommend recycling equipment, such as industrial balers, that will work for your waste output and budget.

We have helped companies nationwide turn the concept of successful waste management into a tangible reality.

Are you interested in learning more about vertical or horizontal industrial balers? Contact our Equipment General Manager, Tom, at (260) 494.5676 or [email protected].

Maximizing Your Industrial Baler’s Lifespan

The Importance of High-Quality Servicing by Quincy Recycle

We could start this blog by saying that industrial balers need maintenance to maximize their lifespan like any piece of equipment – but you probably already knew that. Instead, we’d like to focus on the quality of the service you trust to maintain your equipment.

Equipment jams, oil puddles, and gaps between parts don’t usually happen suddenly. Over time, minor issues become big problems. By the time they’ve become noticeable, it could be too late to avoid a costly repair.

Prevent unexpected repairs and downtime by working with a high-quality, reliable partner to service your industrial baler. Our technicians use advanced diagnostic tools and pay attention to the small details so signs of wear and tear and potential problems don’t go unnoticed. High-quality preventative maintenance is important, and here’s why you can expect just that from Quincy Recycle.

Quincy Recycle works with our customers to establish a quick and convenient preventative maintenance schedule.

We understand maintenance and repair downtime can interrupt daily processes. Our team works with clients to schedule monthly, quarterly, bi-annually, or yearly inspections in advance so you can prepare for maintenance checks. Equipment manufacturer, type, model, usage, and input/output volume determine how often you should service your vertical or horizontal baler for peak performance.

In the event that an issue occurs unexpectedly or major repairs are needed, we offer baler and recycling equipment for sale, lease, or rent to keep your daily processes moving smoothly. Rental options are in stock, so we can respond quickly when our clients need temporary or long-term contract equipment solutions.

Scheduled preventative maintenance helps protect baler and employee safety.

You may not initially connect equipment maintenance with workplace safety, but preventive care helps provide a safe working environment for employees regarding baler function. A functioning, well-maintained baler is less likely to pose safety risks, allowing employees to operate or work around it without worrying about sudden malfunctions that could lead to accidents or injuries.

We also believe that an informed team is a safe and efficient one. We encourage you and your employees to ask questions during inspections. Along with being skilled technicians, our team is made up of educators ready to share their knowledge about new features, best practices, and a deeper understanding of equipment mechanics. We want you to see Quincy Recycle as a partner in your waste management and recycling equipment processes, so we provide our clients with the equipment training they need to be safe and succeed.

Identify baler warning signs of potential issues or breakdowns before they become serious problems.

The first step in preventive care is understanding the warning signs. By identifying potential problems before they occur, businesses can reduce downtime and repair costs.

Industrial balers often give off warning signs (some subtle) that suggest they may be experiencing issues or on the verge of a potential malfunction.

Here are common indicators to look out for:

Unusual Noise Levels: Increased noise or sudden sounds that are out of the ordinary, such as banging, scraping, or grinding, can indicate that parts within the baler are worn out or misaligned.

Decreased Output Efficiency: If the baler starts to process materials slower than usual or requires more cycles to complete tasks previously done quickly, a problem with the machine’s efficiency is usually to blame.

Blockages: Baler chambers can become blocked with debris and waste materials. Safely remove any excess buildup in or around the machine. Check your equipment’s user manual for instructions on how to clean your baler safely.

Inconsistent Bale Sizes or Weights: Bale dimensions or weight variations are often a symptom of issues with the machine’s settings or wear and tear in its compression mechanisms.

Increased Energy Usage: An unexplained spike in energy consumption can suggest that the baler is straining to perform its basic functions, possibly due to mechanical issues.

Visible Wear and Tear: Regular inspections might reveal frayed wires, hydraulic leaks, loose bolts, or cracks in the equipment. Visible damage is a clear indicator that parts may need to be repaired or replaced.

Safety and Emergency Stops Engaging More Frequently: If the baler’s safety features or emergency stops activate more often than normal without clear reasons, an underlying problem could need immediate attention.

Error Messages or Alarms: Modern balers are equipped with diagnostic systems that display error messages or sound alarms when the equipment malfunctions. Noting these alerts and responding promptly can prevent more severe damage.

Our technicians perform routine diagnostic and visual checks to ensure everything is running as it should, but you or your employees should also monitor equipment performance between maintenance checks. Recognizing indicators early on allows Quincy Recycle to address issues before they become significant problems, protecting the investment you’ve made in your recycling equipment.

Protect Your Investment with High-Quality Servicing from Quincy Recycle

Taking proactive steps to maintain your industrial baler ensures it remains a reliable asset in your recycling and waste management plans.

At Quincy Recycle, we help businesses maximize the lifespan of their industrial balers through high-quality servicing. Our team provides the expertise and support to keep your recycling operations running smoothly, safely, and efficiently.

To schedule regular inspections or immediate repairs, call Quincy Recycle at 800.311.6097 or contact us online.